Cargo Tank Pressure Monitor & Control System on Ship

Cargo Tank Pressure Monitor System or Cargo Tank Pressure Monitoring & Control System are essential in ensuring the safety and efficiency of the transportation of liquids and gases. With their ability to prevent overpressure or vacuum condition and improve operational efficiency, these system are an essential part of the logistic and transportation industry.

It's important to consider the pressure range of the cargo when selecting a cargo tank pressure monitoring system. Different cargos have different pressure requirements, and the monitoring system must be able to accurately measure the pressure within that range. For example, some cargos may need to be transported at high pressure, while others may need to be transported at low pressure.

C argo Tank Pressure Monitoring & Control System Certification and Calibration

Calibration of cargo tank pressure monitoring systems are important steps in ensuring that the systems is provide reliable & accurate data. The calibration process involves adjusting the system to ensure that it is providing accurate reading of the cargo tank pressure, involves comparing the reading from the system to the actual pressure of the cargo, and making adjustment as necessary.

Certification is the process of verifying that a cargo tank pressure monitoring system meets certain standards and specifications. This typically involves testing the system to ensure that it is providing accurate and reliable data, and that it meets any relevant industry standards.

Cargo Tank Pressure Monitor & Control System Calibration should be done regularly, at least once a year or as specified by the manufacturer, to ensure that the system is providing accurate data. The calibration procedure should be performed by trained technicians who have the knowledge and skills to properly calibrate the Cargo Tank Pressure Monitor System.

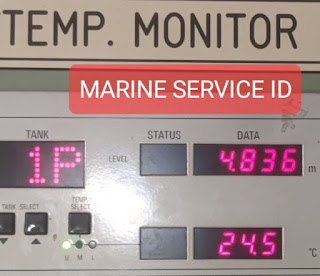

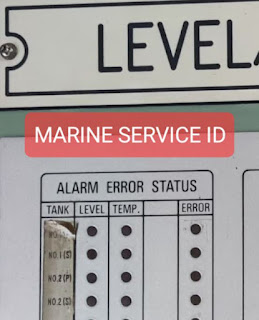

MARINE SERVICE ID Ship Calibrations & Certification Services

MARINE SERVICE ID has a Technical Team who are well - trained,reliable and experienced in Cargo Tank Pressure Monitor System Calibration and Certification at the fleets of various Shipping Company in Indonesia Sea and Ports area.

Click the link for Business Inquiries : Customers Relation

MARINE SERVICE ID Indonesia Marine Service also provide Calibration, Certification, Repair, Troubleshooting, Supply, Installation, Reprogramming Services of Ship Instrumentations Controls and Ship Automations Controls, includes ;

Portable Single Gas Detector Certification & Calibration Services

Portable Multi Gas Detector Certification & Calibration Services

H2S Hydrogen Sulfide Gas Detector Certification & Calibration Services

Overfill Level Alarm System Certification & Calibration Services

Gas Analyzer Certification & Calibration Services

CO2 Carbon Monoxide Gas Detector Certification & Calibration Services

High Level Alarm / HLA Certification & Calibration Services

High High Level Alarm / HHLA Certification & Calibration Services

VAS / Vapour Alarm System Certification & Calibration Services

Pressure Calibrator Certification & Calibration Services

Toxic Gas Detector Certification & Calibration Services

Temperature Calibrator Certification & Calibration Services

Inert Gas System / IGS Certification & Calibration Services

Smoke Detectors Certification & Calibration Services

Fire Alarm System Certification & Calibration Services

O2 Oxygen Gas Analyzer Certification & Calibration Services

Inert Gas Generator / IGG Certification & Calibration Services

Cargo Pump Temperature Alarm Certification & Calibration Services

OWS 15 ppm Oil Water Separator / Bilge Separator Certification & Calibration Services

Electrical Measuring Instruments Certification & Calibration Services

Fixed Gas Sampling System Certification & Calibration Services

Pump Room Gas Detection System Certification & Calibration Services

Ullage Temperature Interface / UTI meter Certification & Calibration Services

Manifold Cross Over High Pressure Alarm Certification & Calibration Service

Manifold Cross Over Temperature Certification & Calibration Service

Pressure Monitoring System Instruments Certification & Calibration Service

Temperature Monitoring Instruments System Certification & Calibration Service

Float Level Gauges Instruments Certification & Calibration Service

Cargo Tank System Local Instruments Certification & Calibration Service

Cargo Tank System CCR / Cargo Control Room Instruments Certification & Calibration Service

Cargo Tank & Void Space Local Pressure Instruments Certification & Calibration Service

Cargo Tank Local Temperature Gauges Instruments Certification & Calibration Service

Cargo Liquid & Vapour Manifold Outboard Certification & Calibration Service

Cargo Liquid & Vapour Manifold Inboard Certification & Calibration Service

Cargo Manifold Temperature Gauges Certification & Calibration Service

Visit other Marine Service Id service sites :

Marine Services & Supply Indonesia

Read other articles from CargoMonitoringSystem.Com :